A biotech team formed at FIT has won the Conservation X Labs Microfiber Innovation Challenge, a competition seeking solutions to the pollution caused by microplastics. Werewool, co-founded by Chui-Lian Lee, Textile Development and Marketing ’18; Valentina Gomez, Textile Development and Marketing ’20; and Theanne Schiros, PhD, associate professor of Science, was one of five winners among applications from 19 countries. A panel of seven expert judges selected the winners based on feasibility, growth potential, environmental impact, and the novelty of their approach. Werewool took home a share of a $525,000 prize pool and are eligible for an additional $25,000 in funding.

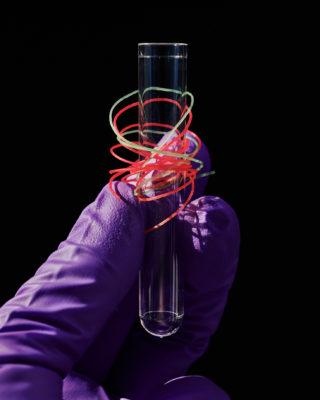

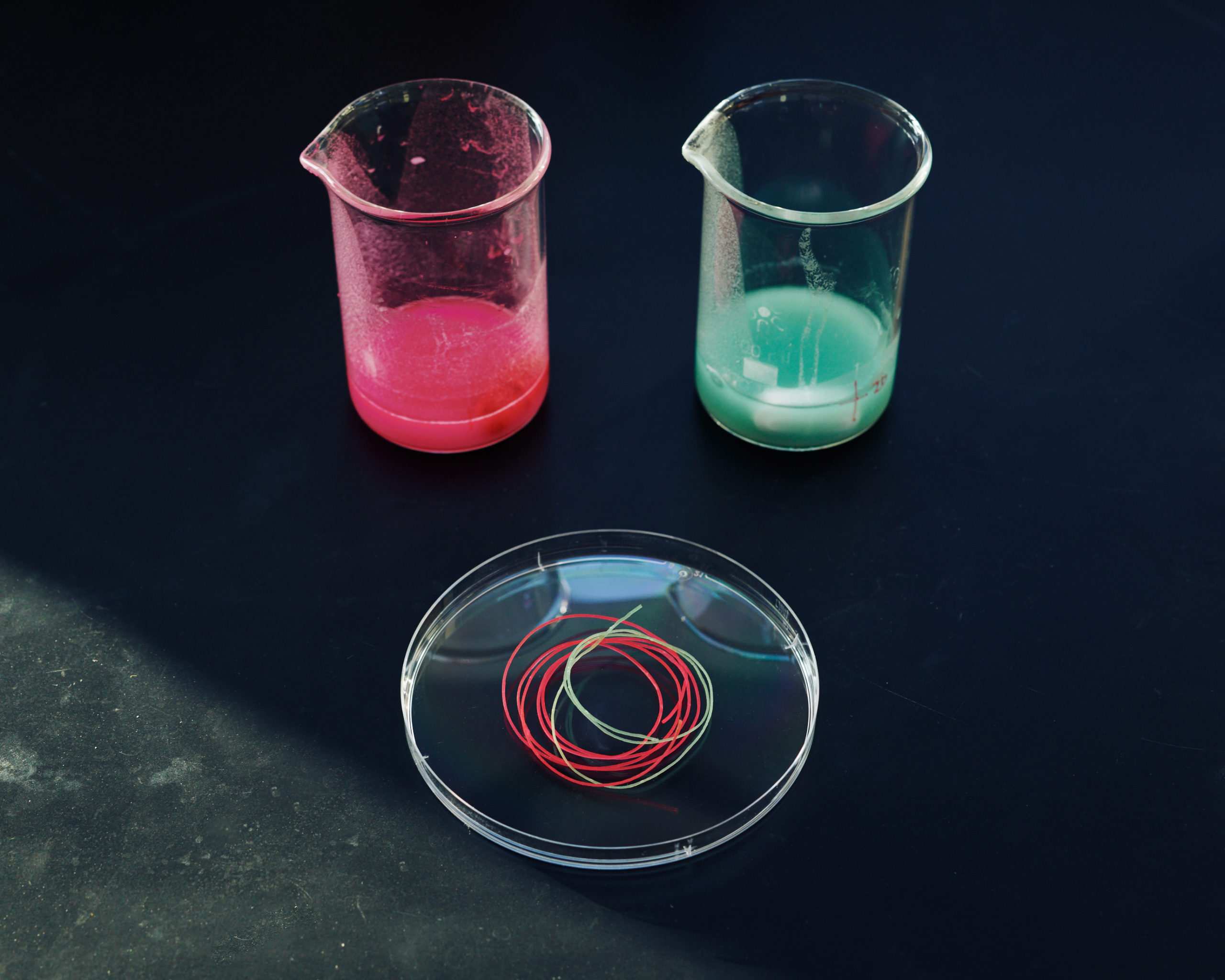

Werewool was formed at FIT in 2018 as a student project that entered the Biodesign Challenge, a global undergraduate biotechnology competition. Now the company designs fibers with performance properties like color and stretch built in. While these properties are inspired by structural proteins that already exist in nature, Werewool uses the tools of biotechnology to redesign and engineer these proteins to form fibers with biopolymers which can be sourced from existing agricultural waste streams. The fibers are nontoxic and designed to be biodegradable at the end of garment’s useful life.

“Nature did a lot of R&D for us,” Schiros, Werewool’s chief science officer, says.

Lee, CEO of the company, believes their holistic, sustainable viewpoint has been key to their success. “We’re looking at the entire lifecycle of the product,” she says. “Our goal is that, at the end of its useful life, it will go back into the earth.”

The prize gives the startup both recognition on a global stage and much-needed funding. They are also seeking investors to build their team of polymer scientists, materials scientists, bioengineers, and research assistants. Lee and Gomez have also been doing an incredible amount of market research to lay the groundwork to eventually bring the fiber to market. Right now, the fibers are hand-extruded from a syringe; within two years, Werewool aims to produce enough fiber to feed a circular knitting machine.

The Werewool team needs to be transdisciplinary because producing a new fiber requires not just scientific research and textile development but also navigating complex supply chains and savvy marketing. But these challenges are what makes the project so exciting for the Werewool team—and, they hope, the new generation of students at innovation-focused colleges like FIT.

“This new fiber innovation space breaks down the barriers between fields,” Schiros says, “because you have to.”