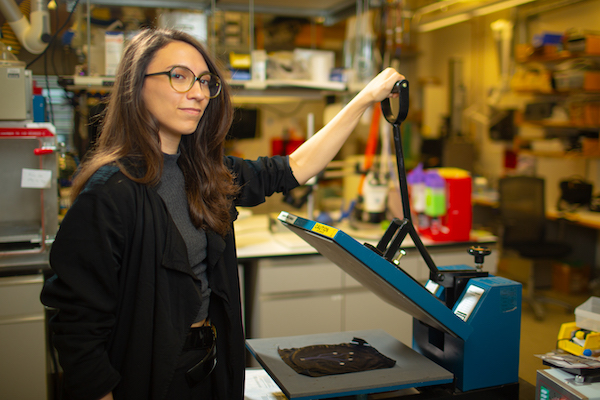

At the Wyss Institute for Biologically Inspired Engineering in Boston, Fashion Design alum Vanessa Sanchez developed robotic textiles that could revolutionize myriad industries. For her research, she was named to the prestigious Forbes 30 Under 30 list, in the Science category.

Robotic textiles can change size, shape, and temperature in response to stimuli. For example, clothing could shrink or expand to help people with limited mobility get dressed, vibrate selectively to help wearers navigate, or vary their coverage in response to fluctuating body temperatures.

“These fabrics can ‘understand’ something about the environment and about their interactions with a person and respond accordingly,” Sanchez says.

The field of wearable robotics began to flourish in the early 2000s, but early devices were rigid and uncomfortable. Fabric-based devices were introduced in the 2010s, but true robotic textiles, which can sense and respond to their environment without the need for stiff components, have only emerged in the past few years.

At the Wyss Institute, a Boston research consortium drawing on expertise from Harvard, MIT, and other nearby institutions, Sanchez helped create a soft, flexible sensor that can be sewn into clothing unobtrusively and hug the body, providing greater comfort and more accurate movement detection. She also helped develop a textile with inflatable compartments that can apply therapeutic pressure to muscles to prevent bed sores or deep vein thrombosis. The pouches contain a fluid that turns to gas when pressure sensors are activated, inflating the textile without a bulky and noisy pneumatic system.

A decade ago, Sanchez enrolled at FIT to learn how clothing was constructed, but her questions ranged beyond the scope of her coursework. At that time, FIT’s textile offerings were not as science-oriented as they are today.

“I kept wanting to know why we were doing things in certain ways and delving deeper on my own,” she says. “I also had challenges with my own clothing. I had a jacket that was supposed to be waterproof, but I hiked in a typhoon and got soaked. I wanted to know why that failure happened.”

She transferred to an undergraduate fiber science program at Cornell, then brought her apparel design skills to robotics teams at the Wyss Institute. Now she is a PhD candidate at the Harvard John A. Paulson School of Engineering and Applied Sciences.

As a woman in a male-dominated field, she felt alone at first, and some colleagues underestimated her. “If I knew how to sew, I must not know the electrical side of things. But no, I can actually do both.” She adds that fashion design requires a complex skill set. “It’s a different set of tools, a different training, but there’s value in both.”

Sanchez isn’t sure how she was nominated for the Forbes honor. An editor reached out to her last October with questions; a few weeks later, she woke up to a handful of text messages from friends. “Why is everyone congratulating me?” she wondered. “I was pretty surprised but happily so—excited that people find the work I’m doing as cool as I do.”