At the FIT/Infor DTech Lab, students and faculty work with industry to experiment with innovative technologies that could shape the future of design, manufacturing, and retail. Recently, the lab investigated 3D digital draping software.

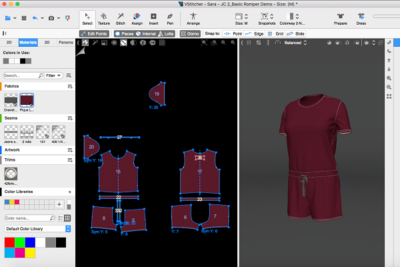

Over the 2017-18 academic year, students Lucy Chen, Fashion Design, and Stephanie Hutton, Technical Design, working with Leonard Bess, assistant professor of Fashion Design, tested a range of 3D modeling programs for apparel companies. These programs create a lifelike digital mannequin, so that patterns can be corrected without physical samples, thus reducing costs and waste and shrinking the design timeline significantly.

“3D design is very efficient for the industry, helping companies become sustainable and save money,” Chen says. “Companies need to realize how important this technology is.”

“Our research was to understand what 3D does and doesn’t do,” Hutton explains. “It’s really good at doing your everyday classic styles, like polos, button-downs, zip-ups, and hoodies. When I tried to make a strapless pleated dress, it got very, very complicated.”

After surveying the most popular programs, Chen, Hutton, and Bess chose to focus on Browzwear, because it accurately renders garments on a virtual mannequin. They experimented with Browzwear and gave feedback to the developers.

“It takes a couple of days to make a 3D sample,” Hutton says. “If the pattern’s perfect, it could take a couple of hours. But it takes weeks to get a physical sample.”

When the DTech trial ended, Hutton applied for and won a highly competitive 3D design internship at PVH—the first of its kind in company history—using Browzwear to fast-track designs for its Heritage Brands: Arrow, Bass, Izod, and Van Heusen. She is now working there part-time while completing her studies.

Chen was hired part-time at PVH as 3D materials librarian, also a newly created position. For Browzwear to replicate a fabric properly, that fabric needs to be entered into the system. At PVH, Chen uses Browzwear’s fabric analyzer to do bend and stretch tests, so that the fabric drapes correctly in the program. Then she irons the fabric and scans it into the computer to get an image of its texture. She also enters trims and embroidery into the system as needed.

At FIT, Bess is developing a course in 3D digital design, to debut as early as fall 2019, that will teach students this sought-after skill, giving them a hiring advantage when they graduate. The course will also be available through the Center for Continuing and Professional Studies.

“Tech companies are moving into the fashion space, and this is keeping apparel CEOs awake at night,” Bess says. “But 3D design companies don’t have enough staff to train as many users as the industry needs. We at FIT can do that.”

“There’s a real sense in the air that people are coming out of FIT prepared for the future of the industry,” says Michael Ferraro, executive director of DTech.