When in-person classes were halted in March 2020, faculty scrambled to reinvent their curricula for remote delivery. They came up with creative solutions, especially challenging for hands-on courses. Here are four of countless examples of courses that shine online.

In TY 421: Advanced Hard Toy Design and Engineering, students typically build prototypes of hard toys in FIT’s state-of-the-art lab, but when classes moved online, SUNY Distinguished Teaching Professor Judith Ellis and her team substituted 3D printing for lab work. Faculty member Joseph Masibay and James Pearce, manager of the Innovative Technology and Digital Production Group, showed students how to digitally model their toys in SolidWorks. Then, using a new industrial-grade high-resolution 3D printer, Pearce’s team in the FabLab produced and mailed toy parts to the students, allowing them to present a fully functioning toy vehicle by semester’s end. “We’ll never go back to teaching the way we did,” Ellis says.

For Lori Massaro, professor of Fashion Business Management, it was easy to move her courses in Computer-Aided Product Development (FM 341 and 441) online. Most of the technology used in the curriculum is cloud-based, and the lab component became more streamlined when students could share files and receive feedback seamlessly. Importantly, the shift to remote meetings mirrored the same shift by industry, a change that experts predict will linger after the pandemic. In other words, according to Massaro, students need to learn on a virtual platform to be better prepared for the workforce. Collaborating remotely, she says, “I find we get a more personal connection.”

Prior to the pandemic, Jean Marc Rejaud, professor of Advertising and Marketing Communications, had been setting up partnerships with institutions to help raise FIT’s profile in the advertising industry. He trained members of the Association of National Advertisers in shopper marketing and taught at ISCOM, a college in France specializing in communications and advertising. When COVID-19 struck, he taught these seminars remotely—and then applied lessons learned to his courses at FIT.

Rejaud found that attention spans are shorter on digital platforms, so he broke up his lectures with frequent polls and small-group discussions. This meant he couldn’t cover the material as quickly, but he supplemented class time with videos that students watched in between classes. He also met with students individually, to reduce the distance brought on by remote learning. One benefit of teaching online is that he can easily bring in speakers from around the world.

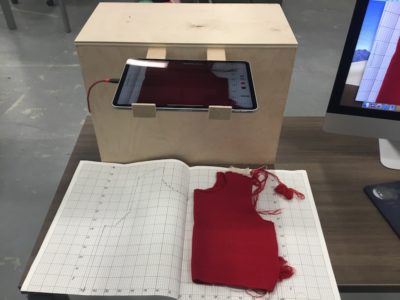

In TS 461: Weft Knit Fabrication and Finishing Techniques, Fashion Design students usually learn how to operate the industrial machines in FIT’s Knitting Lab. Marian Grealish-Forino, adjunct assistant professor of Textile Development and Marketing, and technologists Kathryn Malik and Bernd Wyss worked to replicate that experience for students at home. Through trial and error, they recorded demonstrations on the large, complex Stoll knitting machines; a custom-built box held an iPad above Grealish-Forino while she operated the equipment.

They also mailed students yarn kits to teach them to knit and apply trims by hand. To make final garments, the team programmed the Stoll machines according to students’ specifications, then mailed them the pieces to be assembled at home.

“They ultimately did finish their garments,” Grealish-Forino says. “We really pulled it off.”