The worst of the pandemic may be largely over, but the waste from everyone’s face masks isn’t. Now three Textile Development and Marketing faculty members—assistant chair Ajoy Sarkar and assistant professors Huipu Gao and Imran Islam—working with FIT students, have received a $75,000 P3 (People, Prosperity, Planet) Environmental Protection Agency (EPA) grant to try to solve that problem by developing one-of-a-kind reusable, antiviral face masks made from plastic waste.

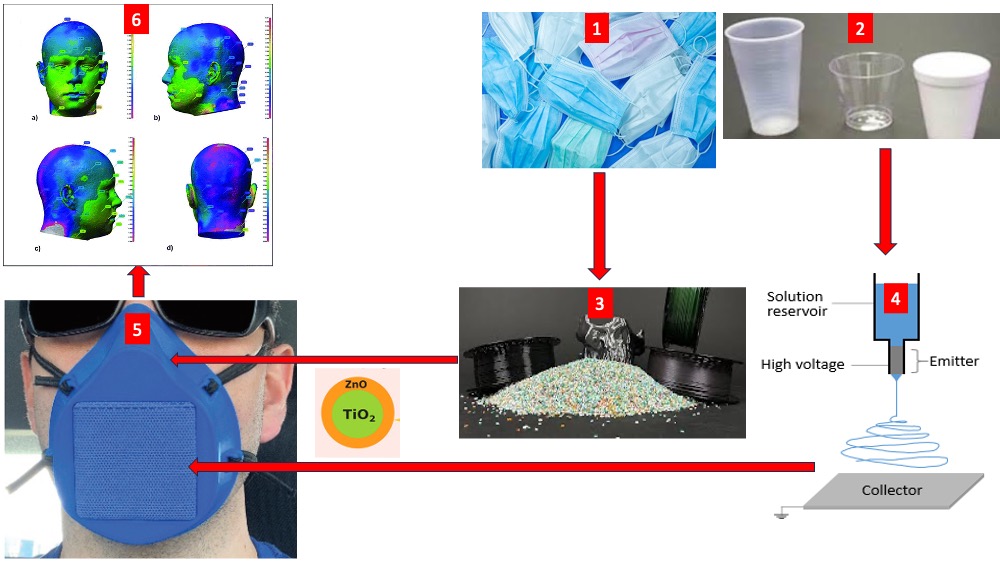

Now in phase one, which will be devoted to the collection of plastic waste, such as Styrofoam and plastic utensils as well as discarded face masks, the project will go into the end of next year and conclude with the evaluation and testing of the masks. The second phase includes the development and evaluation of reusable nanofiber filters, while the third phase will focus on the fabrication and evaluation of a 3D-printed face mask. The finished prototype will be benchmarked against the N95 face mask.

The project will provide invaluable educational opportunities on sustainability principles by directly involving undergraduate students throughout the research, incorporating the project into multiple courses. At end of grant next year, the team will present their findings to a national audience and industry professionals at the P3 Expo.

The students working on the project are Milla Lima and Alisha Singh, both Textile Development and Marketing ’25, and Jenna Richard, Technical Design ’25.

“The whole idea is that during the pandemic, and even now, all these masks were going to the landfill. How can we prevent that and make them into something useful using high-tech textile manufacturing methods?” Sarkar said. “The EPA thought this was novel and innovative, and as far as we know there is nothing like it.”